Story

“We are the idea generators and pace setters on the journey to climate neutrality at BASF”

Wind gusts sweep over a kilometer-long stretch of beach. Waves break on the offshore sandbanks with the rise and fall of the tides, and sea currents make swimming in the sea on some days a dangerous undertaking.

The weather and sea conditions around Zandvoort, a popular destination for surfers and bathers on the Dutch North Sea coast, have never really been of much interest to BASF. That will change beginning in 2023, when the largest, subsidy-free offshore wind park in the world starts up operations. Then BASF will be delighted about strong wind conditions.

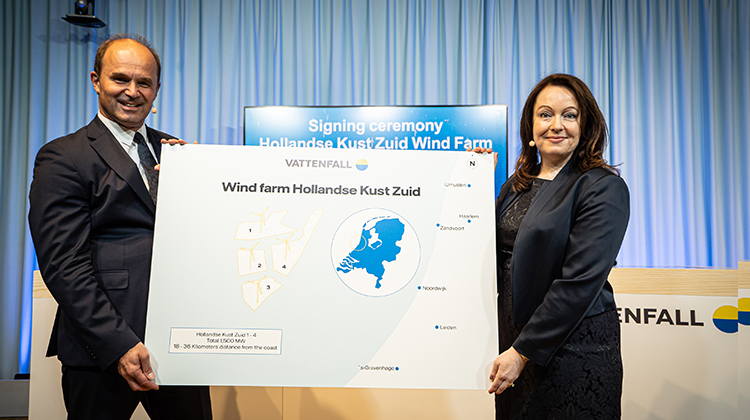

Vattenfall is currently building the Hollandse Kust Zuid wind park between Zandvoort and The Hague up to 18 kilometers off the coast, securing for BASF as its industrial partner a huge amount of green electricity on its journey towards climate neutrality.

Wind park surrounded by the natural forces of wind and water

The construction work started last summer. Ships, cranes, helicopters and fearless workers transport huge foundations made from steel and rotor blades nearly hundred meters long out to sea to build a power station surrounded by the natural forces of wind and water. Each foundation is specially constructed for the site. The largest and heaviest weighs in at 955 tons and is 75 meters high. “Building an offshore wind park is an extremely challenging task,” says Dr. Stefan Käshammer. He is an expert for the evaluation and application of renewable energy technologies and works for BASF Renewable Energy GmbH.

He didn’t have to think for very long when he was offered an opportunity to work with newly established renewable energy team roughly three years ago. Renewable energy is future-oriented and close to his heart. At the beginning there was in many ways a start-up atmosphere, but there was also some doubt if a special team for green energy was really necessary. In the meantime, the skepticism has given way to greater approval. Many want to get on board. “That gives us a strong tailwind,” says Käshammer happily.

“During the construction phase of the wind park, we cannot just simply go out and check on the status of the project. Only visitors with prior consent and appropriate safety instruction are allowed,” explains Dr. Tobias Stäb. He works together with Käshammer in the same team and is Project Leader at BASF for Hollandse Kust Zuid. “But we are very well informed about the construction progress through our good contact with Vattenfall.” Stäb was equally passionate about the idea of working to supply BASF with renewable energy.

We deliver green energy to every BASF location in Europe.

The BASF subsidiary Renewable Energy GmbH, established in 2022, grew out of a team with a handful of employees. Horatio Evers, Managing Director, says: “We deliver green energy to every BASF location in Europe.”

But why does BASF need such huge amounts of green electricity?

Biggest transformation in the history of BASF: Achieving net zero emissions by 2050

Climate protection, responsible use of resources as well as the circular economy are anchored in BASF’s corporate strategy. BASF wants to reduce its greenhouse gas emissions by 25 percent compared with 2018 and to have net zero emissions by 2050. These ambitious plans underscore BASF’s commitment to the Paris Climate Agreement and support the EU’s project of the century to make Europe the first climate neutral continent by 2050. That is an immense task facing BASF as well as other companies. Over 20 percent of the largest listed companies in the world have committed themselves to net zero emissions.1

Climate neutrality is only possible with the chemical industry

The chemical industry has a key role to play on the journey to climate neutrality. On the one hand, their products lay the foundation for a sustainable life. Without the innovations from the chemical industry there would be no electric cars on the road, solar cells would not be able to convert sunlight into electricity, and wind turbines would not rotate.

On the other hand, the chemical industry consumes an enormous amount of energy, currently provided largely by fossil fuels such as natural gas and oil. The production of basic chemicals alone is responsible for roughly 70 percent of the greenhouse emissions at BASF.

It is the biggest transformation in the history of the chemical industry and for BASF.

“We can only reach climate neutrality if we completely change our production, replacing energy sources based on fossil fuels with electricity from renewable resources. That will require entirely new processes and technologies and the courage to think in new directions,” says Dr. Martin Brudermüller, Chairman of the Board of Executive Directors of BASF. “It is the biggest transformation in the history of the chemical industry and for BASF.”

The electrification of chemistry requires enormous amounts of green electricity

BASF tests new technologies in pilot plants and invests huge sums if they show promise. Electrically heated steam cracker furnaces are one example of this, which could reduce emissions by as much as 90 percent. With the electrification of chemistry, BASF is undertaking groundbreaking work, yet at the same time it will drastically increase its demand for energy from renewable sources. “After the conversion in 2035, the Ludwigshafen site alone is expected to require three to four times more green electricity than in 2022 to reach its zero emissions goal. We also need to consider that in our procurement of electricity,” says Horatio Evers.

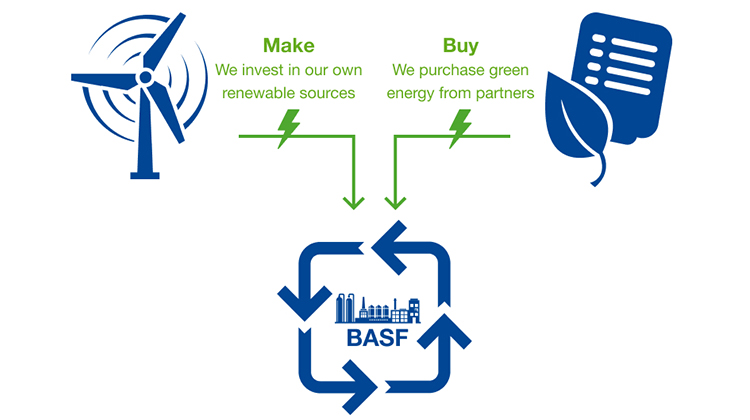

Renewable energies need to be massively expanded globally. “But that is happening too slowly. That is why we are pushing ahead to secure access to green electricity,” says Evers. BASF is focusing on the “make and buy” strategy: “On the one hand, we invest in the construction of our own production plants, and on the other hand, we purchase green electricity on the market and make long-term supply agreements.”

There’s no way of getting around offshore wind parks

“Solar, wind on land or sea, bioenergy or hydrogen – there are a number of technologies and possible partners. We consider at least three criteria before making our decision,” says Dr. Roland Merger. As Vice President of Renewable Energy, he is responsible for the global investment strategy for BASF’s green electricity projects and heads up the wind park projects at BASF.

What are the criteria? The technologies must be economical, produce a sufficient quantity of electricity for BASF and be socially accepted. “Looking at these criteria, it becomes clear that there is no way of getting around offshore wind parks. They are one of the most efficient forms of generating electricity from renewable sources and play an important role for BASF,” says Merger.

Hollandse Kust Zuid – the world’s first fully commercial offshore wind park

“With Vattenfall, we have, strategically speaking, thrown our hat into the ring and found a partner that will help us on our way to becoming climate neutral,” says Merger. BASF has secured a nearly 50 percent share of Vattenfall’s offshore wind park Hollandse Kust Zuid and will receive a significant amount of green power in return. It is BASF’s first large investment in renewable electricity plants. “The energy will be used to supply BASF’s Antwerp Verbund site, the second largest BASF Group site worldwide. It is the first fully commercial offshore wind farm in the world, which translates into full exposure to market risk,” explains Merger.

With the energy companies Ørsted and Engie, BASF is taking another approach. BASF has concluded supply contracts with both companies for a term of 25 years, the longest-term power purchase agreements (PPAs) for offshore wind energy yet announced.

PPA

A power Purchase Agreements (PPA) is a special supply contract for electricity generated by renewable resources, which is generally concluded for longer time periods of several years. They offer suppliers – in this case Ørsted and Engie – security, for instance, in the planning of new plants. Customers, like BASF, secure large amounts of green electricity.

“Our project pipeline is full and that will remain that way”

“Electricity trading in Europe plays an important role for us,” says Evers. Stefanie Müller has been taking care of that since January. “There are huge price fluctuations in the electricity market depending on the season and geopolitical situation. Electricity is traded on exchanges just like shares,” Müller explains. “We want to take advantage of that to protect BASF from price risks and secure electricity from renewable sources at competitive prices.” She finds her new job particularly appealing as it combines sustainability with traditional trading in energy.

Electricity is traded on exchanges just like shares.

Electricity trade, projects like Vattenfall, Ørsted and Engie and other green electricity supply contracts – “Our project pipeline is full and that will remain that way,” says Evers and adds: “The road to net zero CO2 emissions at BASF will not be easy but a huge challenge, demanding all our power. We see ourselves as the idea generators and pace setters on the journey to climate neutrality.”

BASF is building solar parks

BASF is not only investing in offshore wind parks, but also in solar. Together with enviaM-Gruppe, a leading regional energy service provider in eastern Germany, BASF in Schwarzheide is planning to build a solar park as a joint venture, which should start operations in 2022. Furthermore, 88 BASF sites are already powered by emission-free energy from water, solar or wind energy.

Installation vessels put to sea following winter break

Construction work at Hollandse Kust Zuid in the North Sea is halted over the winter, due to bad weather and rough seas; in a few weeks, however, the installation vessels will put to sea again. Vattenfall will install the remaining foundations at depths of up to 28 meters and complete construction of the wind farm by 2023. Afterwards, Dr. Stefan Käshammer will only check the weather report now and then: “There are only a few days in the year when there is a lull, and the blades stand still. Based on experience, there is enough wind at sea to rotate the turbines.” Once all the 140 turbines go into operation next year, he hopes to be able to stand on one of the platforms at sea with a good view to the wind farm: “That will be a great moment.”

1 Economist, “The world in 2022”