Energy and Climate Protection

As an energy-intensive company, we are committed to energy efficiency and global climate protection. We want to reduce emissions along the value chain. To achieve this, we rely on efficient technologies for generating steam and electricity, increased use of renewable energies, energy-efficient production processes and comprehensive energy management, among other things. Our climate protection products make an important contribution toward helping our customers avoid emissions.

![]()

Strategy

- New climate protection target: CO2-neutral growth until 2030

- Carbon management bundles measures to reduce greenhouse gas emissions

Climate protection is very important to us. As a leading chemical company, we want to achieve CO2-neutral1 growth until 2030: We aim to keep total greenhouse gas emissions from our production sites and our energy purchases stable at the 2018 level while growing production volumes. Sharp increases due to the startup of large-scale plants will be progressively offset. When deciding on investments and acquisitions, we systematically consider the effects on greenhouse gas emissions.

We want to reach our climate protection target and enable further reductions with plant optimization measures, by purchasing low-carbon energy, and with a research and development program to reduce our greenhouse gas emissions over the long term. We have bundled these measures in our carbon management program. In addition, we will also consider temporarily taking external offsetting measures such as purchasing certificates if the technical or economic environment does not permit a stabilization of emissions at the 2018 level using the above approaches.

Most of BASF’s greenhouse gas emissions are attributable to the consumption of energy. At sites with internal supply capabilities, we primarily rely on highly efficient combined heat and power plants with gas and steam turbines, and on the use of heat released by production processes. Furthermore, we are committed to energy management that helps us analyze and further improve the energy efficiency of our plants on an ongoing basis. We continuously analyze potential risks to our business operations arising in connection with the topics of energy and climate protection and derive appropriate measures.

We offer our customers solutions that help prevent greenhouse gas emissions and improve energy and resource efficiency. Around half2 of our annual research and development spending goes toward developing these products and optimizing our processes.

Our climate protection activities are based on a comprehensive analysis of our emissions. We report on greenhouse gas emissions in accordance with the Greenhouse Gas Protocol as well as the sector-specific standard for the chemical industry. As part of the implementation of BASF’s strategy, we have made changes to how greenhouse gas emissions and energy are reported from 2019 onward. For ease of comparison, the 2018 figures have been adjusted according to the new method and target.

- The emissions of BASF SE subsidiaries that are fully consolidated in the Group financial statements in which BASF holds an interest of less than 100% are included in full in emissions reporting (previously: emissions included on a pro rata basis). The emissions of proportionally consolidated joint operations continue to be disclosed pro rata according to our interest.

- We report on emissions and energy for BASF operations including the businesses acquired from Bayer in 2018 and excluding the deconsolidated oil and gas business. The businesses acquired from Bayer are accounted for from January 1, 2018.

- We use the market-based approach (previously: location-based approach) to report on greenhouse gas emissions from purchased energy (Scope 2) for the purpose of our climate protection target. Both approaches continue to be presented in the overview of greenhouse gas emissions in accordance with the Greenhouse Gas Protocol.

Since 2004, we have participated in the international non-profit organization CDP’s program for reporting on data relevant to climate protection. BASF achieved a score of A– in CDP’s rating for 2019, thus attaining Leadership status again. Companies on the Leadership level are distinguished by factors such as the completeness and transparency of their reporting. They also pursue comprehensive approaches in managing the opportunities and risks associated with climate change as well as emissions reduction strategies to achieve company-wide goals.

Climate protection is a shared global task. We advocate climate protection by supporting initiatives to this end. For instance, BASF spearheaded the World Economic Forum’s initiative on Collaborative Innovation for Low-Carbon Emitting Technologies in the Chemical Industry. In July 2019, BASF and the World Economic Forum invited participants to a kick-off workshop in Ludwigshafen, Germany. Representatives from 20 international chemical companies met with the goal of accelerating CO2 reduction through future cooperation. BASF also supports the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD). In 2019, we shared learnings and best practices on the implementation of the TCFD recommendations with four industry peers at a TCFD Preparer Forum for Chemicals. For the first time, this report includes an overview showing the sections and subsections in which TCFD-relevant information can be found.

1 The goal includes other greenhouse gases according to the Greenhouse Gas Protocol, which are converted into CO2 equivalents.

2 Costs not relevant to the calculation of this share include research expenses in early innovation stages of the phase-gate process, patent costs and expenses for supporting services.

Global goals and measures

We want to achieve CO2-neutral growth until 2030. In other words, we aim to maintain total greenhouse gas emissions from our production sites (excluding emissions from sale of energy to third parties) and our energy purchases at the 2018 level (21.9 million metric tons of CO2 equivalents) while increasing production.

2030 target

CO2-neutral growth:

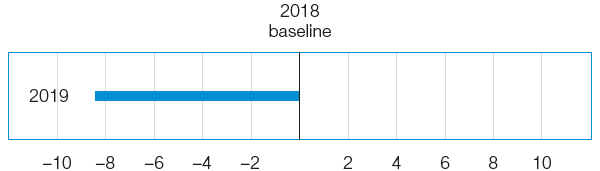

Annual greenhouse gas emissions compared

with baseline 2018

(BASF operations excluding sale of energy to third parties, including offsetting)

constant

In 2019, the emissions reported under this target amounted to 20.1 million metric tons of CO2 equivalents, a decrease of 8.2% compared with the previous year (2018: 21.9 million metric tons of CO2 equivalents). This is primarily attributable to shutdowns of large-scale plants for maintenance work, among other reasons. In addition, energy supply agreements were updated and measures to increase energy efficiency and optimize processes were implemented. We expect emissions for 2020 to increase to the 2018 level, due among other factors to fewer scheduled major shutdowns and the acquisition of Solvay’s polyamide business.

BASF operationsb |

2019 |

2018 |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||

Scope 1c |

|

|

||||||||||||

CO2 (carbon dioxide) |

15.855 |

17.025 |

||||||||||||

N2O (nitrous oxide) |

0.598 |

0.677 |

||||||||||||

CH4 (methane) |

0.025 |

0.027 |

||||||||||||

HFC (hydrofluorocarbons) |

0.082 |

0.091 |

||||||||||||

Scope 2d |

|

|

||||||||||||

CO2 |

3.519 |

4.067 |

||||||||||||

Total |

20.079 |

21.887 |

||||||||||||

Offsetting |

0 |

0 |

||||||||||||

Total after offsetting |

20.079 |

21.887 |

||||||||||||

Sale of energy to third parties (Scope 1)e |

|

|

||||||||||||

CO2 |

0.763 |

0.773 |

||||||||||||

Total |

20.842 |

22.660 |

||||||||||||

Use of biomassf |

|

|

||||||||||||

CO2 |

0.004 |

n/a |

||||||||||||

Greenhouse gas emissions from BASF operations (excluding sale of energy to third parties) compared with baseline 2018 %

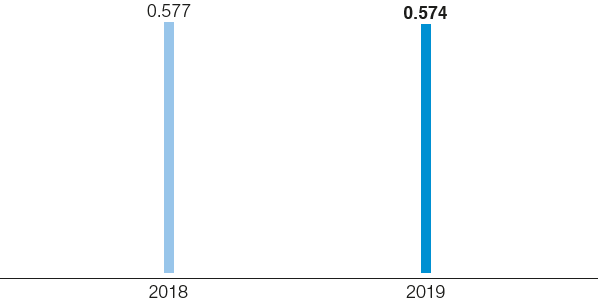

Specific greenhouse gas emissions in 2019 amounted to 0.574 metric tons of CO2 equivalents per metric ton of sales product,3 0.5% lower than in the previous year. Since 1990, we have been able to lower our overall greenhouse gas emissions from BASF operations by 49.9% and even reduce specific emissions by 75.0%.

Specific greenhouse gas emissions from BASF operations4

Metric tons of CO2 equivalents per metric ton of sales product3

3 Sales product volumes include sales between BASF Group companies; merchandise is not taken into account.

4 We have changed the method used to calculate the relevant environmental indicators compared with the previous year. Further information can be found above. The figures for 2018 have been adjusted according to the new method.

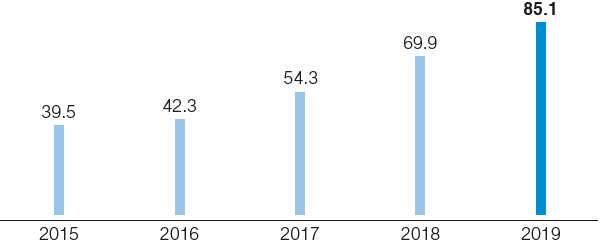

By 2020, we want to have introduced certified energy management systems (DIN EN ISO 50001) at all relevant production sites.5 Together, these represent 90% of BASF’s primary energy demand. This is how we intend to identify and carry out improvements in energy efficiency, reducing not only greenhouse gas emissions and saving valuable energy resources, but also increasing our competitiveness.

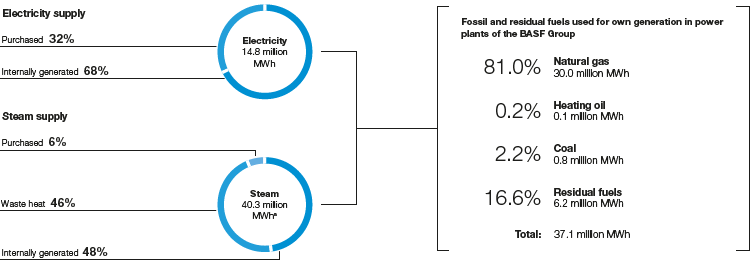

Energy supply of the BASF Group 2019

a Conversion factor: 0.75 MWh per metric ton of steam

The introduction and implementation of certified energy management systems is steered by a global working group. All energy efficiency measures are recorded and analyzed in a global database and made available to BASF sites as best practices. We are currently pursuing more than 200 measures to reduce energy consumption and increase competitiveness. Further sites across all regions were certified in accordance with ISO 50001 in 2019. These include the Verbund site in Kuantan, Malaysia, as well as another 18 sites in the United States, Brazil, Chile, China, India, Germany, France, the Netherlands, Belgium, Poland and Spain, among other countries. At the end of 2019, 82 sites were certified worldwide, representing 85% of our primary energy demand.

Certified energy management systems (ISO 50001) at BASF Group sites worldwide, in terms of primary energy demand4

%

4 We have changed the method used to calculate the relevant environmental indicators compared with the previous year. Further information can be found above. The figures for 2018 have been adjusted according to the new method.

|

2019 |

2018 |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||

Specific greenhouse gas emissionsb (metric tons of CO2 equivalents per metric ton of sales productc) |

0.574 |

0.577 |

||||||||

Primary energy demandd (million MWh) |

58.520 |

60.586 |

||||||||

Energy efficiency (kilograms of sales productc per MWh) |

598 |

626 |

||||||||

3 Sales product volumes include sales between BASF Group companies; merchandise is not taken into account.

4 We have changed the method used to calculate the relevant environmental indicators compared with the previous year. Further information can be found above. The figures for 2018 have been adjusted according to the new method.

5 The selection of relevant sites is determined by the amount of primary energy used and local energy prices.

Energy supply and efficiency

- Internal supply and Verbund system as important components of our energy efficiency strategy

Gas and steam turbines in combined heat and power plants enable us to fulfill more than 70% of the electricity demand of the BASF Group. Compared with separate methods of generating steam and electricity, we saved 12.4 million MWh of fossil fuels and prevented 2.5 million metric tons of carbon emissions in 2019. In 2019, internally generated power in the BASF Group had a carbon footprint of around 0.26 metric tons of CO2 per MWh of electricity and was below the national grid factor at most BASF Group locations. The figure for purchased electricity in 2019 was around 0.46 metric tons of CO2 per MWh (market-based approach). As part of our carbon management, we therefore aim to reduce the carbon footprint of purchased electricity.

Energy saved in 2019 by the Verbund and combined heat and power generation

31.6 million MWh

The Verbund system is an important component of our energy efficiency strategy: Waste heat from one plant’s production process is used as energy in other plants. In this way, the Verbund saved us around 19.2 million MWh in 2019, which translates to 3.9 million metric tons less CO2 released into the environment. With combined power and steam generation as well as our optimized Energy Verbund, we were thus able to prevent a total of 6.4 million metric tons of carbon emissions in 2019.

We further improved the resource and energy consumption of our production in numerous projects around the world in 2019. At the Verbund site in Ludwigshafen, Germany, for example, we were able to save considerable amounts of steam and therefore primary energy with predictive, model-based process control systems at two production plants. Process improvements at many other sites have also led to savings in steam, electricity and fuel.

We also rely on locally available sources to supply our sites with energy. We are increasingly incorporating the use of renewable energies, especially purchasing electricity. Our research also contributes to increasing the efficiency of technologies for the use of renewable energy sources.

Carbon footprint and climate protection products

- Reporting on greenhouse gas emissions along the entire value chain

- Customers’ use of BASF climate protection products avoids greenhouse gas emissions

BASF has published a comprehensive corporate carbon footprint since 2008. This reports on all greenhouse gas emissions along the value chain. It also shows, on the basis of selected climate protection products, the emissions avoided through the use of these products.

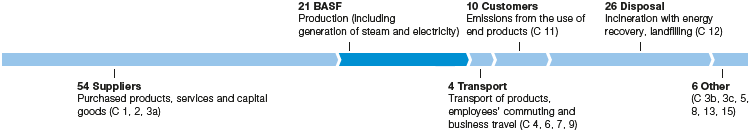

The greenhouse gas emissions arising before and after BASF’s activities in the value chain (Scope 3 in accordance with the Greenhouse Gas Protocol) amounted to around 100 million metric tons of CO2 equivalents in 2019 (2018: 118 million metric tons of CO2 equivalents). The significant decrease compared with the previous year is attributable to the deconsolidated oil and gas business, which is no longer included in the carbon footprint as of 2019. However, this decrease is partly offset by a new methodological approach to calculate the emissions from the disposal of our products. These emissions are estimated based on a closed carbon cycle, taking into account regional disposal methods.

Our climate protection products offer our customers solutions to avoid greenhouse gas emissions over their entire lifecycle as compared with reference products. The systematic analysis we conduct on our portfolio – Sustainable Solution Steering – rates the use of these Accelerator solutions as particularly good with respect to climate protection and energy.

Examples of Accelerator solutions are our expandable polystyrene granulates (EPS) Styropor® and Neopor®. Both products are used to insulate buildings and help to save heating energy and reduce carbon emissions. Neopor® contains particles of graphite. This enables the production of insulation boards with up to 20% better insulation performance than conventional EPS. Another polystyrene-based climate protection product is Styrodur®, an extruded rigid foam panel, which likewise offers optimum insulation performance and a wide range of potential applications, especially under high pressure.

Greenhouse gas emissions along the BASF value chain in 2019a

Million metric tons of CO2 equivalents

a According to Greenhouse Gas Protocol; Scope 1, 2 and 3; categories within Scope 3 are shown in parentheses. For more information on Scope 3 emissions reporting, see basf.com/corporate_carbon_footprint

An analysis shows that the volumes of Styropor®, Neopor® and Styrodur® sold in 2019 help our customers to save 62 million metric tons of CO2 emissions over the entire lifecycles of these products when used to insulate existing buildings. This calculation is based on a lifecycle analysis that takes into account the production and disposal of the insulation materials and compares the energy consumption of a renovated building with that of an unrenovated building over a period of 50 years. The calculation of avoided greenhouse gas emissions took into account the chemical industry standards of the International Council of Chemical Associations (ICCA) and the World Business Council for Sustainable Development (WBCSD). All three products also help to reduce carbon emissions in new buildings, where they have been used as standard for decades.

BASF also offers biomass balance (BMB) versions of Styropor®, Neopor® and Styrodur®. In accordance with an externally certified mass balancing method, 100% of the fossil raw materials used in the production of these BMB products are replaced by renewable raw materials such as bio-naphtha or biogas. This saves carbon emissions and fossil resources during the manufacturing process. Together with the German EPS insulation material manufacturer Bachl, we calculated in a lifecycle analysis that the use of renewable raw materials reduces carbon emissions from the production of Neopor® BMB insulation boards by 66% compared with conventionally produced Neopor® boards (based on one cubic meter of insulation board).

Other innovative climate protection products for thermal insulation applications include BASF’s new high-performance polyurethane-based and mineral-based insulation materials, SLENTITE® and SLENTEX®, which offer even more efficient insulation at lower thicknesses compared with conventional materials.